A Family Legacy of Innovation

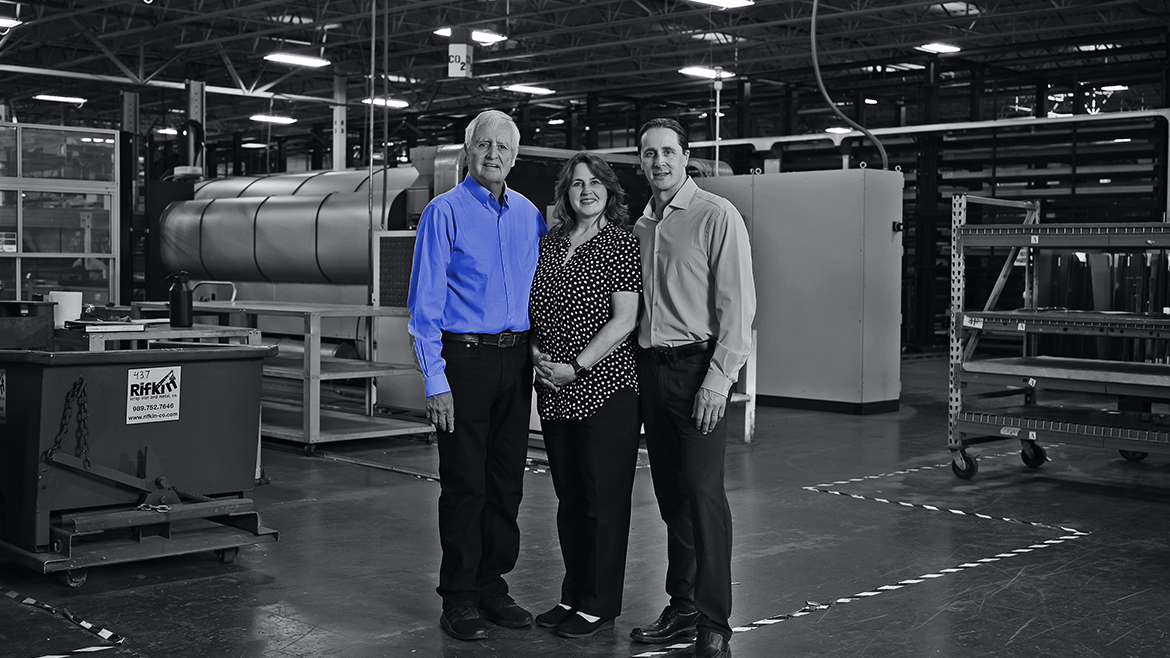

Some people build a better mousetrap. In 1969, Jon D. Hall built a better, faster, more sanitary glass washer: the Glastender. Not only the world’s first automatic rotary glasswasher but also the name of the small manufacturing shop he launched shortly thereafter, Glastender today is a family-owned, family-run manufacturing force — one still based in Jon’s hometown of Saginaw, Michigan, but now powered by 200+ employees who crank out innovative food service equipment and systems to commercial kitchens and bars around the world.

It’s also a darn nice place to work.

There are many reasons for Glastender’s growth and success over the last 54 years, and Rehmann’s proud to have played a part in 35 of them, but not a single moment of that story can be told without going back before Glastender’s beginnings, for a brief look at Jon’s.

A born-and-raised Saginaw kid who began tinkering with cars long before he was licensed to drive one, Jon bought his first car the summer after eighth grade. As his youngest son, Todd, tells it, Jon got the money for the car from Old Man Wesley across town, who bought the Whizzer motorbike Jon had won in a local contest by tricking out a bicycle with — family legend is fuzzy on details here — some sort of spinning merry-go-round dolled up with safety slogans. Two weeks later, Jon traded that first car for another, better ride, courtesy of a guy whose wife couldn’t figure out the stick shift.

Jon, you see, had an eye for good-looking machines. He had a mechanical mind, too. But most importantly, whatever machine he got his hands on, he was determined to improve.

That penchant served him well when he began working part-time for his dad’s ice-machine rental business, Equipment Distributing Company (EDC), around age 14. It earned him a reputation in the bars and restaurants they serviced as the kid who could fix just about anything.

Problem was, by the time Jon turned 21, “He was,” says Jon’s daughter Kim, “sick of fixing other people’s crap.”

A Manufacturer is Made

In 1964, at age 24, Jon invented the world’s first automatic ice dispenser. (Its auger system, which drops ice down at the push of a button, is ubiquitous; you’ve seen one in action any time you’ve filled an ice bucket in a hotel.)

He took his invention to Erie, Pennsylvania, to show the factory folks who produced the Kold Draft ice machines he and his father rented out around central Michigan. The Erie people liked it. They wanted it. There was just one catch: They didn’t want to manufacture Jon’s machine. They wanted Jon to.

As Jon explained in the March 2023 Ordinary People, Extraordinary Things podcast, that’s when the proverbial die was cast: “I learned about manufacturing because I had to make it back here and ship it to them.”

While Jon continued working with his dad at EDC, he continued building his ice machines, initially relying on local fabricating companies to make the parts he needed and then assembling and testing them himself. As the operation grew, he purchased his own welding and sheet metal fabrication equipment, learning how to operate them and even developing some of his own techniques. Still, his capacity was limited. So was demand. He shipped some machines down to Erie, sold a couple to local hospitals. But he never let up on looking for problems to solve, then building, testing, tinkering, testing, and tinkering some more — with both products and processes — until he solved them.

“He’s just always been that ‘I can build a better mousetrap’ kind of guy,” says Todd.

Kim nods. “Yes, there’s always got to be an easier, better way to do things.”

Enter invention No. 2, the Glastender, a major time- and space-saving improvement on the straight-line conveyor-style drinking-glass washers of the time. Bartenders — and, as such, bar owners — loved it.

Local customers bought up the Glastender washers as quickly as Jon could make them. Ditto for the cocktail station pass-through version he created next. Throughout the ’70s, while still working full-time at EDC, Jon invested in growing Glastender.

In an effort to get Glastender seen beyond mid-Michigan, Jon began participating in the annual National Restaurant Association show in Chicago in 1973. He incorporated the company in ’74; moved operations from a small, leased factory in downtown Saginaw to a 12,400-square-foot facility a few miles outside downtown in ’76; and continued to develop more and more products for what’s known in the bar and restaurant industry as the underbar — home to the stainless-steel sinks, ice bins, rotary glass washers, and other gear bartenders need to keep the party going.

Before long, Jon had earned an all-new reputation among and restaurants Glastender served: the guy who made such quality equipment, you never needed a repairman.

The only thing missing? For a married father of four who still worked full-time for his dad’s company and on Glastender at night (yet still hadn’t yet drawn a paycheck; he opted instead to invest Glastender’s earnings right back into Glastender until the early ’80s), Jon lacked only time.

So in 1979, he made a decision that would change the course of his and Glastender’s future. He brought on a business partner, Jay H. Kegerreis, a graduate of Wake Forest University whose expertise in business, sales, and finance rivaled Jon’s genius in product development.

Over the next decade, despite a tanking economy and runaway inflation, the partners capitalized on their unique skillsets to push Glastender forward, going for — and getting — multiple national accounts; expanding the plant’s footprint; and buying a refrigeration company, one with terrific foam technology but infuriatingly cheap products Jon knew he could build better.

Jon and Jay had a clear goal: Make Glastender a one-stop shop for every bit of equipment — nay, every bit of sleek, useful, reliable, high-quality equipment — a commercial bar would need.

With an average 25 percent annual growth through the ’80s, Glastender was well on the way to achieving that goal. But as you’d expect from a manufacturer managing a new national presence, rapidly expanding its product offerings, and trying to meet each leap in demand with evermore investment in materials, labor, and equipment, there was more to be done than two leaders and roughly two dozen employees could — unless, of course, Jon and Jay were willing to relax their quality standards, or abandon their goal.

Spoiler alert: They weren’t.

Of Tragedy & Transitions

The trajectory of Glastender over the next 10 years was nothing short of astonishing. Rather than pump the brakes, Jon and Jay called in reinforcements. They brought Rehmann on in 1988 to ease and manage Glastender’s increasing load of finance responsibilities, recruit some key talent, and advise them on strategies to keep the business profitable and growing.

Some of that talent was the Hall kids themselves. Each one had grown up in the business, spending, since age 14, their after-school hours, summers, and school breaks either working on the factory floor or in the back office. As young adults, each pursued different passions but, one by one, became interested in applying what they’d learned to the family business.

Son Todd, a musician and out-of-the-box thinker with a BA in business from the University of Michigan, signed on as an inside sales associate in ’91, joining his bandmate and eldest brother, Jon, who preferred working the shop floor.

Rick, the second eldest, who at age 16 had helped Jay implement the company’s first accounting software (and later earned a bachelor’s in computer engineering and a Ph.D. in computer science), wrote a computer program to help Glastender track inventory.

While pursuing her master’s in nursing and rising through the management ranks of a massive home-healthcare company, Kim watched Glastender’s explosive growth with pride — and not just a little concern.

Between 1990 and 1995, Glastender had launched two new products and a nationally touring mobile design facility, plus undertook two more major plant expansions, doubling the plant’s size once, then adding on 60,000 more square feet shortly afterward. Not surprisingly, the number of employees had ballooned, too.

“I distinctly remember Kim saying, ‘Dad, you know, you guys are pushing 90 employees, and you don’t even have an employee manual,” says Todd.

Or an H.R. manager.

Or any H.R. policies.

Or, for that matter, any documented procedures.

Kim says she doesn’t recall exactly how the conversations evolved into her decision to leave nurse management for Glastender, but she distinctly remembers that the switch wasn’t meant to be permanent: “I loved what I did and where I worked, but … it was like, ‘OK. I’ll come and help develop some H.R. policies and procedures and do it kind of temporarily.’”

You know what they say about the best-laid plans, right? Two unavoidable realities upended this one.

The first would reveal itself to be devastating: Jay had been diagnosed with a brain tumor. Though treatment was underway, and hopes were high, the prospect of losing Jay — the yin to Jon’s yang, the arc to Jon’s electrode, the grease to the ever-turning wheels in Jon’s “I-can-make-it-better” brain — weighed heavily on Glastender’s people and its future prospects.

The second, far less frightening, was plain immutable fact: Apples really don’t fall far from their tree. So the moment Kim walked in Glastender’s door to begin her “temporary” stint that late October day in 1996, it was evident that shoring up the status quo simply wasn’t in her blood.

She saw the way Glastender, despite its massive outward successes, had been running on the inside — “…very loosey-goosey, definitely a mom ’n’ pop place,” she says — and she knew she could make it run better.

“I was talking about professionalizing the whole organization the minute I got there. One of the things I did right away is [host] small group meetings with the employees and asked, ‘What do you love? What do you hate? What would you wish for?’ Just to kind of get a feel for it,” she says.

The feedback was, well … telling.

“I remember telling [my dad], ‘You know what? You need more than just H.R. policies and procedures here. We have to find a way to get this plant operating. And I don’t know anything about production, but you have to be able to run this plant in a more efficient manner, in a better way.’”

Tops on her list of must-do’s: Send Jon to LEAN manufacturing seminars. Push Glastender to formalize its management team. Ensure each person with a “manager” title understands their responsibilities and has the tools to manage effectively. Carve out specific roles for and empower the next generation of leaders —Todd, herself, and her husband, Mark (then plant manager), included. Trim waste, strengthen structure, and be ready for change.

Kim’s efforts came not a moment too soon. Barely one year after her arrival, in January 1998, Jay H. Kegerreis passed away.

The Next Generation

Losing Jay was a heartbreaking milestone in Glastender’s history. Jay, says Todd, had been more than a partner and friend to Jon; he had been a mentor.

“Dad, even though he can talk to people, and he can sell and all that jazz — he can get the job done — he does not like all the operations, paperwork side of things. He just wants to design products, make some stuff,” Todd says. “And that’s what Jay enabled Dad to do for 19 years. But when Jay passed away, we had been there, kind of a second string available in the wings. While we might not have thought specifically about succession planning, the way it happened — me, Mark, and then Kim coming on board full-time, and early enough to learn the ropes before Jay passed away – turned out to be a great succession plan.”

“My dad does not fit the typical patriarchal image of wanting to control everything,” Todd adds. “He’s more — if you demonstrate competency, he’s more than happy to let you run with it.”

So run they did.

For the next 25 years, the Hall kids would work to create the bandwidth their dad needed to keep developing the kind of products that had earned Glastender its spotless reputation for innovation and exceptional quality. But more than that, they would devote themselves to ensuring the company’s inner workings earned that reputation too.

Their goal: to take the value and spirit their dad had brought to Glastender and infuse it throughout the company through employee development and engagement, empowering everyone at Glastender to, as Todd explains, “successfully grow the company without needing Jon or even us, for that matter, having our hands on every little detail. We leveraged the teamwork concept.”

Key to that team effort was Rehmann.

Along the way, Todd, Kim, Mark (now president, vice president of administration, and vice president of operations, respectively) and the other members of the executive leadership team, would lean on Rehmann time and again — “not just for financial stuff,” says Todd — but also for strategy, recruitment, employee engagement, leadership training, business valuation, estate planning, tax planning, and more.

Todd and Kim point to Rehmann’s welcome impact on the turbulent years before and after Jay’s passing, when Glastender began transitioning the company from a loosely managed organization to a more professional one — inciting the ire, subsequent (but ultimately failed) push to organize under the Teamsters, and, shortly thereafter, departure of many change-resistant employees.

“‘The kids” were running the company and expecting different things from employees,” says Todd. “That culture change was too much for some employees, and they decided to get off the bus.”

What could have been perceived as Glastender’s unraveling was, in fact, an auspicious disentangling, a brave split from the weight of the old ways of working that, well … no longer worked for a 21st century manufacturer determined to create a workforce environment as progressive and high-performing as its products.

“We started doing all of our own hiring and bringing in the people we wanted to bring in,” Kim says.

Reformation

Glastender’s executive team capitalized on Rehmann’s deep bench of experts, leaning on advisors of varying specialties to help shape their vision for the future. Together, they worked through the process of identifying and documenting Glastender’s mission and values, trained managers to lead and listen more effectively, and delved into operations to create a strategic plan — each effort never undertaken before but deemed necessary to align all of Glastender’s people to pull together and in the same direction: forward.

Kim says the foundational work they began with Rehmann in those early transitional years quickly led to significant turning points in the company where Rehmann was equally instrumental: like in 2005, when Glastender’s executive team became interested in process-based leadership — basically “a way that we run the company that involves and engages all of our employees,” she explains — and looked to Rehmann to help brainstorm and implement.

The year 2008 brought one of the biggest shifts yet. Kim and Todd were looking for a better way to incentivize their employees and directly engage them, at all levels, in the company’s performance. Todd came across a little-known concept: an open-book style of management, wherein leaders regularly share the company’s income statement and relevant operating data with all employees as a way of showing exactly where, when, and how much their performance moves the proverbial profit needle.

Todd admits the concept was so new at the time that Rehmann’s advisors didn’t yet have experience with it. But, he notes, they dug in to learn more, listen, and brainstorm different approaches and concepts with him.

“Just having someone to bounce thoughts off — not that they are going to have all the answers — that doesn’t matter. It’s the value you get out of having other smart people to talk through things with, that’s really important,” says Kim. “So even though they might not have had an exact answer on how we were going to organize our financials with the open-book management, talking to them no doubt helped [us] make a better-informed decision about which way to go.”

Same for the financial workings of the company as a whole: “Helping us with the whole financial piece, educating us, being the experts in that category and bringing the thinking and innovation … and new thoughts as to how we should do things from an accounting and business [perspective],” she adds, “that piece is really big.”

As was Rehmann’s assistance throughout the pandemic: “Huge,” says Kim.

And that embezzling episode, says Todd: “[Rehmann] was there for us, too — big time.”

He tallies the biggest moments on his fingers. “Open-book management? They were there for us. 2009 – there was a cash flow crisis. We called them up, sh*%%ing our pants, and it’s not long before we got a meeting and they’re ‘Well, you got this money here, this money there.’ And they’re helping us think about what funds are available, what we can do to help make changes … The pandemic, oh my god,” he says, remembering Rehmann’s all-hands-on-deck efforts to protect Glastender’s people and business.

“Basically, when something stressful happens, they’re just a really strong partner to lean on, “ he says. “And like Kim said, even if they don’t have the answer, they know someone that does. They’re that levelheaded company that’s like, “OK, tell me what you need.”

Given the company’s steady half-century rise, sterling product reputation, and historically low turnover – “single digit and often low single digit,” says Todd proudly — you might assume that Jon (happily tinkering away in his shop) and the now 30+ leaders and 200+ employees of Glastender (who have so successfully steered Glastender onward and upward, both inside and out) need little in the way of help at this point.

But if you’re thinking that way, maybe you’re not seeing what Jon and the next generation of Glastender do: Room for improvement. A better way to build a better mousetrap. An ever-changing manufacturing environment, industry, and global economy. But most assuredly, with the energy, values, and teamwork Jon and his kids have made part parcel of the company – plus a little help from a levelheaded Rehmann advisor or two – clear proof that Glastender is up for the challenge.